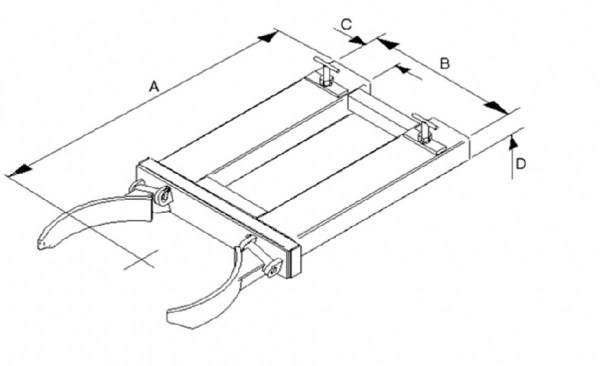

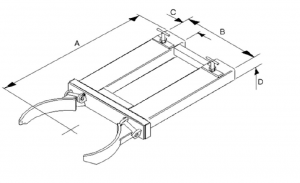

Description

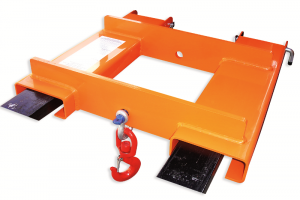

The Universal Drum Handler incorporates a quick-slide-two-position adjustor that allows both steel and ‘L’ & ‘XL’ ring plastic drums to be picked up. Handling these two popular types of drum the universal drum handler is well suited for low to medium movement of drums around the factory or store.

Fully automatic in operation, the drum grab simply locates underneath the ‘rolling hoops’ of the steel drum, or underneath the lip of the plastic drum, and tightens its grip once lifting commences. No manual handling of drums is required, thus reducing risk of injury whilst increasing on site Health & Safety.

With heavy duty zinc plated screw clamps for securing the drum handler safely to the lift truck forks, this drum handler is a simple, low cost yet effective attachment for carrying out your drum handling operations, and like all our forklift attachments, will come fully tested and certified to comply with the latest Health & Safety Regulations.

Features:

• Suitable for use with 210L steel drums and ‘L’ & ‘XL’ ring plastic drums (as shown above), allows these common drums to be handled with no risk of injury

• Ample sized fork pockets to suit most fork trucks, no need to risk back strain through manual handling

• Simple design with few moving parts offering low maintenance and servicing cost

• Fully automatic in operation, reducing time and labour costs

• Quick and easy to fit on and off the forklift with heavy duty zinc plated screw clamps for safe securing to forklift

• ‘CE’ marked and supplied with Certificate of Conformity for Health & Safety Regulations

How does the drum grab handle both steel and plastic drums ?

As part of the design of the drum handler, there is a removable pin, which allows the central arm to move inwards and outwards to accommodate either drum